AHOW connector system

Find out how Flathead's below-wellhead electrical connection technology can save you time in the field during installation while also increasing runtime.

To learn more about how our AHOW system can help you, contact Cam Haworth at the link below.

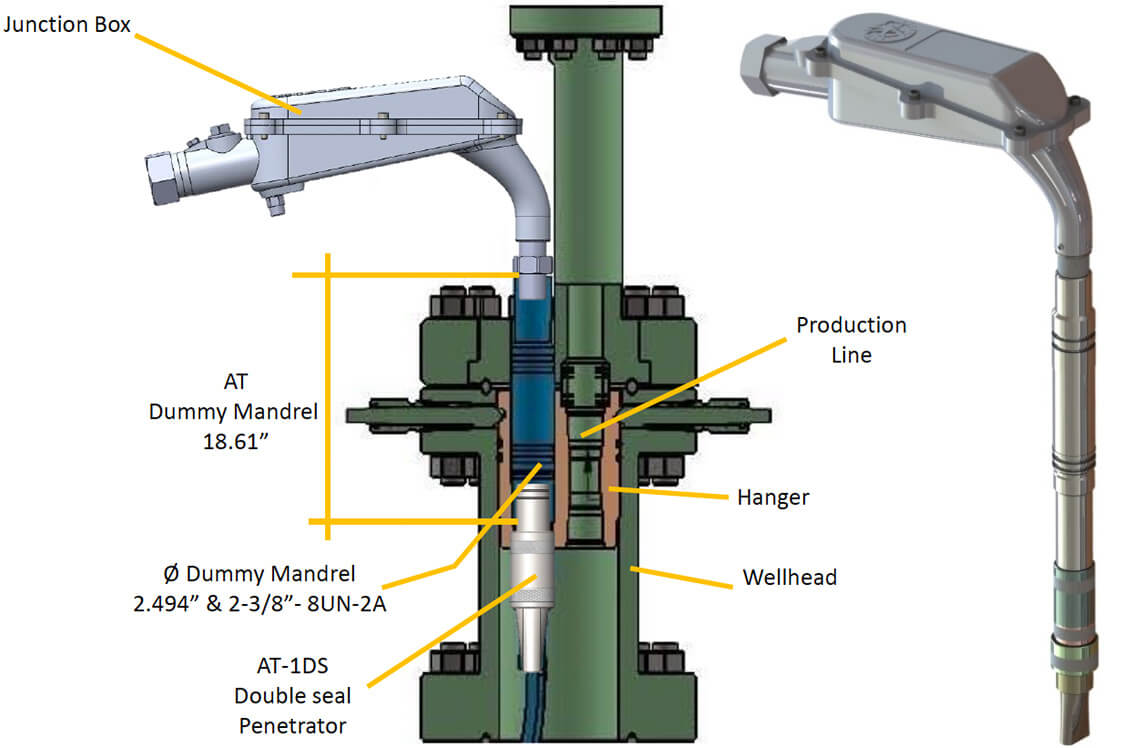

AT-1 Wellhead Penetrator Assembly

Pictured right: AT-1DS Assembly

AT-1 Wellhead Penetrator

The AHOW connector system is a thru-wellhead ESP electrical connection system which eliminates the need for a below-wellhead electrical connection.

A patented system allows the ESP cable to pass through the wellhead with no splices or cuts to the cable, eliminating a potential cable failure point that is found on some other systems.

A dummy mandrel designed for the AT-1 system allows the operator to convert to the AHOW connector system without expensive changes or modifications to the existing wellhead.

AT-1DS SAGD Wellhead Penetrator

The AHOW connector system is a thru-wellhead ESP electrical connection system which eliminates the need for a below-wellhead electrical connection.

Designed for the challenges of SAGD production conditions, the patented system allows the ESP cable to pass through the wellhead with no splices or cuts to the cable, eliminating the potential cable failure point that is found on some other systems. Similar in style to the AT-1 system, the AT-1DS as a level of redundancy by adding a second seal into the system.

A dummy mandrel designed for the AT-1DS system allows the operator to convert to the AHOW connector system without expensive changes or modifications to the existing wellhead.

The AHOW Difference

The design of the AHOW system allows for easy installation under all weather conditions. Extreme cold or wet weather will not hinder installation. With no precision cuts or drying times for epoxies, installation can occur even under less-than-ideal weather conditions.

The design of the two-piece mandrel removes all guesswork when fitting the system together, ensuring a seal without concern over leaks from under-torqueing components or damage to seals from over-tightening.

Flathead and AHOW work with reputable elastomer manufacturers so that we are able to respond to clients specific requests or unique operating conditions.

/01

Existing wellheads are easily adaptable to the AHOW system using a specially designed dummy mandrel. The dummy-mandrel fits into the existing wellhead with the AHOW connector fitting into the dummy mandrel. No changes or replacement of existing wellhead components is required.

/02

Repair kits are available at a fraction of the overall system cost. The main body of the AHOW system is reusable. When a well intervention is required, only the elastomer pieces need to be replaced - the main body of the system can be reused.

The AHOW connector system is a thru-wellhead ESP electrical connection system which eliminates the need for a below-wellhead electrical connection.

A patented system of grommets and mandrels allows the ESP cable to pass through the wellhead with no splices or cuts to the cable, eliminating a potential failure directly below the dognut common on most systems.

The system is available in two styles

single-seal system

The single-seal system is designed for conventional wells.

dual-seal system

The dual-seal system is designed specifically with the SAGD market in mind, able to handle the extreme wellhead temperatures found in thermal recovery projects.

Get in Touch

The AHOW connector system, with years of field experience, is now available in Canada.

Contact us today for more information on how AHOW’s patented technology can save you time in the field during installation while also increasing runtime.